The Solar Simulation Irradiation Test Chamber, also known as the "sunlight radiation protection test device," is categorized into three types based on test standards and methods: air-cooled xenon lamp (LP/SN-500), water-cooled xenon lamp (LP/SN-500), and benchtop xenon lamp (TXE). The differences among them lie in test temperature, humidity, accuracy, duration, etc. It is an indispensable testing instrument in the series of aging test chambers.

The test chamber utilizes an artificial light source combined with G7 OUTDOOR filters to adjust the system's light source, simulating the radiation found in natural sunlight, thereby meeting the requirements for solar simulators as stipulated in IEC 61646. This system light source is employed to conduct light aging tests on solar cell modules in accordance with IEC 61646 standards. During the testing, the temperature on the back of the modules must be maintained at a constant level between 50±10°C. The chamber is equipped with automatic temperature monitoring capabilities and a radiometer to control the light irradiance, ensuring it remains stable at the specified intensity, while also controlling the duration of the test.

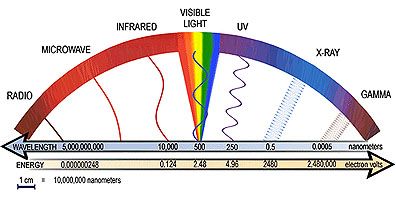

Within the solar simulation irradiation test chamber, the period of ultraviolet (UV) light cycling typically shows that photochemical reactions are not sensitive to temperature. However, the rate of any subsequent reactions is highly dependent on the temperature level. These reaction rates increase as the temperature rises. Therefore, it is crucial to control the temperature during UV exposure. Additionally, it is essential to ensure that the temperature used in accelerated aging tests matches the highest temperature that materials would experience when directly exposed to sunlight. In the solar simulation irradiation test chamber, the UV exposure temperature can be set at any point between 50°C and 80°C, depending on the irradiance and ambient temperature. The UV exposure temperature is regulated by a sensitive temperature controller and a blower system, which ensures excellent temperature uniformity within the test chamber.

This sophisticated control over temperature and irradiance not only enhances the accuracy and reliability of the aging tests but also ensures that the results are consistent with real-world conditions, through this Solar Simulation Irradiation Test Chamber, which can provide valuable data for the development and improvement of solar cell technologies.