AEC-Q100- Failure Mechanism Based on Integrated Circuit Stress Test Certification

With the progress of automotive electronic technology, there are many complicated data management control systems in today's cars, and through many independent circuits, to transmit the required signals between each module, the system inside the car is like the "master-slave architecture" of the computer network, in the main control unit and each peripheral module, automotive electronic parts are divided into three categories. Including IC, discrete semiconductor, passive components three categories, in order to ensure that these automotive electronic components meet the highest standards of automotive anquan, the American Automotive Electronics Association (AEC, The Automotive Electronics Council is a set of standards [AEC-Q100] designed for active parts [microcontrollers and integrated circuits...] and [[AEC-Q200] designed for passive components, which specifies the product quality and reliability that must be achieved for passive parts. Aec-q100 is the vehicle reliability test standard formulated by the AEC organization, which is an important entry for 3C and IC manufacturers into the international auto factory module, and also an important technology to improve the reliability quality of Taiwan IC. In addition, the international auto factory has passed the anquan standard (ISO-26262). AEC-Q100 is the basic requirement to pass this standard.

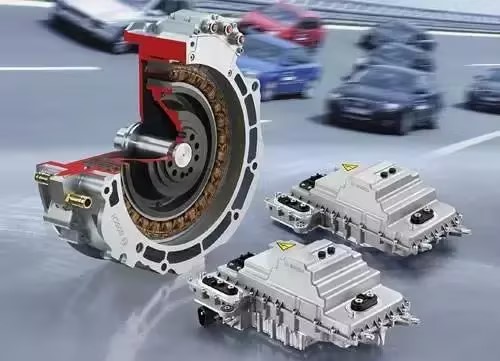

List of automotive electronic parts required to pass AECQ-100:

Automotive disposable memory, Power Supply step-down regulator, Automotive photocoupler, three-axis accelerometer sensor, video jiema device, rectifier, ambient light sensor, non-volatile ferroelectric memory, power management IC, embedded flash memory, DC/DC regulator, Vehicle gauge network communication device, LCD driver IC, Single power Supply differential Amplifier, Capacitive proximity switch Off, high brightness LED driver, asynchronous switcher, 600V IC, GPS IC, ADAS Advanced Driver Assistance System Chip, GNSS Receiver, GNSS front-end amplifier... Let's wait.

AEC-Q100 Categories and Tests:

Description: AEC-Q100 specification 7 major categories a total of 41 tests

Group A- ACCELERATED ENVIRONMENT STRESS TESTS consists of 6 tests: PC, THB, HAST, AC, UHST, TH, TC, PTC, HTSL

Group B- ACCELERATED LIFETIME SIMULATION TESTS consists of three tests: HTOL, ELFR, and EDR

PACKAGE ASSEMBLY INTEGRITY TESTS consists of 6 tests: WBS, WBP, SD, PD, SBS, LI

Group D- DIE FABRICATION RELIABILITY Test consists of 5 TESTS: EM, TDDB, HCI, NBTI, SM

The group ELECTRICAL VERIFICATION TESTS consist of 11 tests, including TEST, FG, HBM/MM, CDM, LU, ED, CHAR, GL, EMC, SC and SER

Cluster F-Defect SCREENING TESTS: 11 tests, including: PAT, SBA

The CAVITY PACKAGE INTEGRITY TESTS consist of 8 tests, including: MS, VFV, CA, GFL, DROP, LT, DS, IWV

Short description of test items:

AC: Pressure cooker

CA: constant acceleration

CDM: electrostatic discharge charged device mode

CHAR: indicates the feature description

DROP: The package falls

DS: chip shear test

ED: Electrical distribution

EDR: non-failure-prone storage durability, data retention, working life

ELFR: Early life failure rate

EM: electromigration

EMC: Electromagnetic compatibility

FG: fault level

GFL: Coarse/fine air leakage test

GL: Gate leakage caused by thermoelectric effect

HBM: indicates the human mode of electrostatic discharge

HTSL: High temperature storage life

HTOL: High temperature working life

HCL: hot carrier injection effect

IWV: Internal hygroscopic test

LI: Pin integrity

LT: Cover plate torque test

LU: Latching effect

MM: indicates the mechanical mode of electrostatic discharge

MS: Mechanical shock

NBTI: rich bias temperature instability

PAT: Process average test

PC: Preprocessing

PD: physical size

PTC: power temperature cycle

SBA: Statistical yield analysis

SBS: tin ball shearing

SC: Short circuit feature

SD: weldability

SER: Soft error rate

SM: Stress migration

TC: temperature cycle

TDDB: Time through dielectric breakdown

TEST: Function parameters before and after stress test

TH: damp and heat without bias

THB, HAST: Temperature, humidity or high accelerated stress tests with applied bias

UHST: High acceleration stress test without bias

VFV: random vibration

WBS: welding wire cutting

WBP: welding wire tension

Temperature and humidity test conditions finishing:

THB(temperature and humidity with applied bias, according to JESD22 A101) : 85℃/85%R.H./1000h/bias

HAST(High Accelerated stress test according to JESD22 A110) : 130℃/85%R.H./96h/bias, 110℃/85%R.H./264h/bias

AC pressure cooker, according to JEDS22-A102:121 ℃/100%R.H./96h

UHST High acceleration stress test without bias, according to JEDS22-A118, equipment: HAST-S) : 110℃/85%R.H./264h

TH no bias damp heat, according to JEDS22-A101, equipment: THS) : 85℃/85%R.H./1000h

TC(temperature cycle, according to JEDS22-A104, equipment: TSK, TC) :

Level 0: -50℃←→150℃/2000cycles

Level 1: -50℃←→150℃/1000cycles

Level 2: -50℃←→150℃/500cycles

Level 3: -50℃←→125℃/500cycles

Level 4: -10℃←→105℃/500cycles

PTC(power temperature cycle, according to JEDS22-A105, equipment: TSK) :

Level 0: -40℃←→150℃/1000cycles

Level 1: -65℃←→125℃/1000cycles

Level 2 to 4: -65℃←→105℃/500cycles

HTSL(High temperature storage life, JEDS22-A103, device: OVEN) :

Plastic package parts: Grade 0:150 ℃/2000h

Grade 1:150 ℃/1000h

Grade 2 to 4:125 ℃/1000h or 150℃/5000h

Ceramic package parts: 200℃/72h

HTOL(High temperature working life, JEDS22-A108, equipment: OVEN) :

Grade 0:150 ℃/1000h

Class 1:150℃/408h or 125℃/1000h

Grade 2:125℃/408h or 105℃/1000h

Grade 3:105℃/408h or 85℃/1000h

Class 4:90℃/408h or 70℃/1000h

ELFR(Early Life failure Rate, AEC-Q100-008) : Devices that pass this stress test can be used for other stress tests, general data can be used, and tests before and after ELFR are performed under mild and high temperature conditions.