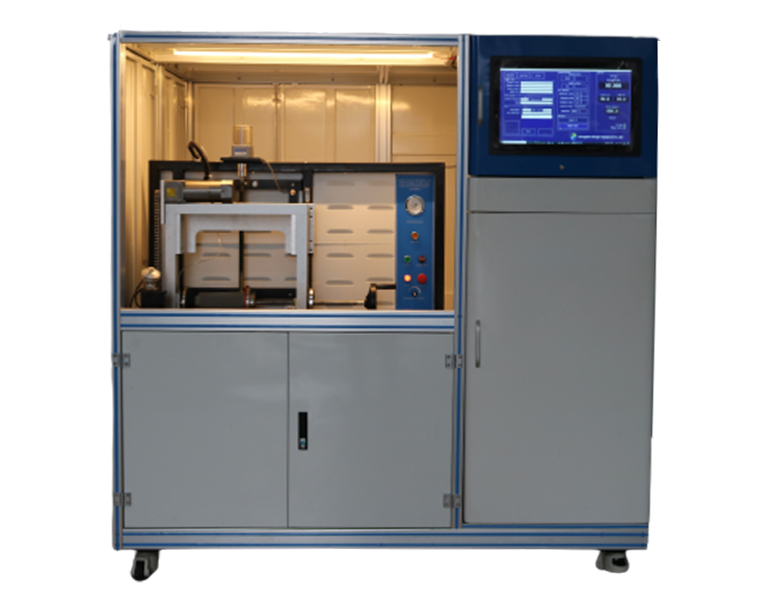

When we want to do a structural integrity verification and bubbling point test for hydraulic filters, we may want to do it by a machine automatically. Then a test stand complying with ISO 2942-2004 may be suitable for doing the test.

It specifies a bubble-point test method for confirming the manufacturing dependability of your filter factor or figuring out the localization in the most significant pore in the filter factor by figuring out the first bubble point. Verification of manufacturing dependability specifies the acceptability in the filter aspects for additional use or tests. The first bubble noint is recognized throuah continuation in the manufacturing intearity testIt is under no conditions an operating sign of a filter element in specific. It cannot be employed for extrapolation for the ideas of purification ranking, performance or maintenance capacity and really should be used for details only.