Hydrocracking bubbling bed technology is an advanced petroleum refining process specifically designed for the deep processing of heavy oil and solid-containing petroleum products. As global conventional crude oil resources gradually deplete, and the trend toward heavier crude oil becomes increasingly evident, hydrocracking bubbling bed technology is playing an increasingly critical role in the energy industry. This technology addresses the dual challenge of global energy shortages and the need for improved energy efficiency, particularly in the context of rapid economic growth in developing countries and the resulting surge in energy demand. Below is a detailed explanation of the hydrocracking bubbling bed process, its key equipment, and industrial applications.

1. Working Principle of Hydrocracking Bubbling Bed Technology

Hydrocracking bubbling bed technology is based on hydrocracking reactions aimed at breaking down large molecular organic compounds in heavy oil and solid-containing petroleum products into smaller, lighter hydrocarbons through the combined action of catalysts and hydrogen. This process improves oil quality, reduces sulfur, nitrogen, and oxygen impurities, and enhances the fluidity and combustion properties of the final product. The core of hydrocracking lies in using hydrogen under high-temperature and high-pressure conditions to cleave large molecules into smaller ones, ultimately yielding high-quality light oil products.

In a bubbling bed reactor, hydrogen is injected at the bottom, mixing with the heavy oil and catalyst to form a fluidized, bubbling state. Due to the extended contact time between the catalyst and the feedstock in this gas-liquid-solid three-phase system, efficient hydrocracking reactions can occur. This technology is especially effective in processing high-sulfur, high-nitrogen, and other impurity-laden feedstocks while significantly improving yield and economic performance.

2. Role of Circulation Pumps (Ebullating Pumps)

Circulation pumps, also known as ebullating pumps, are essential components of the hydrocracking bubbling bed system. Their primary function is to ensure the continuous circulation of feedstock and catalyst within the reactor, maintaining uniform temperature distribution and a stable reaction environment. By circulating the feedstock, the pump ensures thorough contact between the oil and catalyst, thus improving reaction efficiency and preventing localized overheating or catalyst deactivation.

Additionally, circulation pumps help control the reactor's pressure and flow, ensuring the continuous flow of the oil feed. Given the harsh operating conditions in hydrocracking (high temperatures, high pressures, and the presence of solid particles), these pumps must be designed with high resistance to wear, corrosion, and thermal stress. They must also withstand prolonged exposure to extreme conditions while ensuring system stability and efficiency.

3. Process Advantages and Application Fields

Compared to traditional catalytic cracking processes, hydrocracking bubbling bed technology offers several notable advantages:

- Wide Range of Feedstocks: This technology can process a variety of low-quality feedstocks such as heavy oil, residual oil, kerosene, and solid-containing petroleum products, offering strong adaptability.

- High Product Yield: The hydrocracking process efficiently breaks down heavy molecules, increasing the yield of light oil products and resulting in higher overall output than conventional methods.

- Environmental Benefits: The hydrocracking process effectively removes harmful impurities such as sulfur and nitrogen, reducing the pollutant content in the final product and meeting stricter environmental regulations.

- Improved Energy Efficiency: By converting heavy components into more combustible light oil products, hydrocracking significantly enhances energy utilization efficiency.

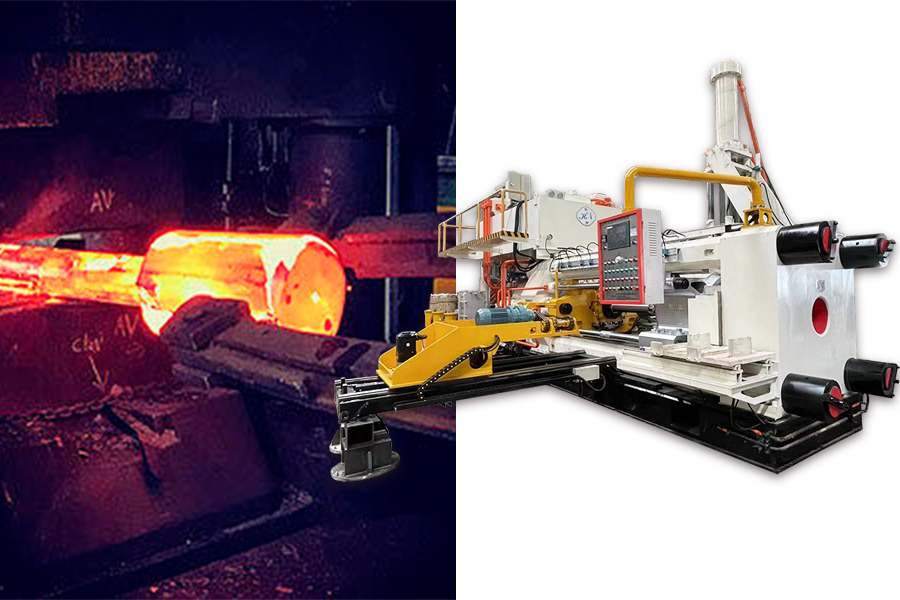

The application conditions of hydrogenation boiling pumps are complex, the medium temperature is as high as 500℃, the inlet pressure is 30MPa, and the medium is highly corrosive. At present, the technology of this product is only mastered by a few countries, and there are very few factories that can produce it, and it is expensive. Fortunately, Huasheng is one of the very few factories that can produce this pump.

In 2018, Huasheng Pumps and Valves undertook the "Residue Oil Hydrogenation Boiling Pump Research and Development" project, a major equipment localization project of Sinopec Headquarters. The company relies on the operating parameters of Sinopec's 2 million tons/year liquid diesel hydrogenation unit for research and development. Its rated flow rate: 835m³/h, head: 79m, temperature: 410℃, wet motor power: 250kw. It took 4 years, and the product was delivered in 2022 and is currently running well. The success of the project has enabled China to break the foreign monopoly on hydrogenation boiling pump technology and reduce costs.

As global energy structures shift and environmental requirements tighten, hydrocracking bubbling bed technology presents significant growth potential. Key future development trends include:

- More Efficient Catalysts: Research and development of more efficient, longer-lasting catalysts will further improve reaction efficiency and product yield.

- Intelligent Control Systems: The application of advanced automation and data analysis technologies will optimize the reaction process, reduce energy consumption, and enhance system stability.

- Expanded Application Range: With ongoing technological advancements, hydrocracking bubbling bed technology is expected to extend into other unconventional resource processing areas, such as coal-to-liquids and oil sands extraction.

The development and application of hydrocracking bubbling bed technology provide an effective solution for the utilization of heavy oil and solid-containing petroleum products. This technology offers a viable path for addressing the depletion of conventional oil resources while meeting the growing demand for energy. Circulation pumps, as a critical component of the process, play a pivotal role in ensuring the success of the entire operation. Looking ahead, as the technology continues to evolve, hydrocracking bubbling bed technology will remain a key player in global energy production and refining, contributing to the sustainable development of the energy sector.