Welcome to our comprehensive guide, where we unravel the intricacies of U-shaped drinking straw production. In a world that constantly evolves, even the simplest of objects undergo innovative transformations. One such transformation is the humble drinking straw, now taking on the dynamic and functional form of the U-shaped straw.

In this blog, we embark on a journey through the world of U-shaped drinking straws, delving into their creation, applications, and the entire production process. From the initial concept to the final packaged product, we'll unravel each step to thoroughly understand how these straws are manufactured and why they're gaining prominence across various industries.

So, whether you're a curious consumer wanting to know more about the straws you use or an entrepreneur seeking to delve into the world of straw production, this guide has you covered. Join us as we dive deep into the world of U-shaped drinking straw production, exploring its applications, production process, considerations for setting up a production line, and much more. Get ready to become well-versed in all things U-shaped straw-related – the knowledge you need is right here at your fingertips.

|

Understanding U-shaped Drinking Straws:

Imagine a drinking straw that's not just a straight conduit but a cleverly designed tool that adapts to various scenarios – that's the essence of the U-shaped drinking straw. These innovative straws have taken the beverage consumption experience to a new level, offering functionality that goes beyond the conventional.

|

Definition and Characteristics:

A U-shaped drinking straw, as the name suggests, features a distinct U-shape along its length. This design departure from the traditional straight straw offers several advantages. The curvature allows for better reach and accessibility, making it ideal for a wide range of users, including those with mobility constraints or specific medical needs. The straws are typically made from safe and food-grade plastic materials, ensuring a seamless and hygienic drinking experience.

Advantages of U-shaped Design:

The U-shaped design of these straws brings forth a host of benefits. It enables ease of use in situations where tilting the head might be difficult or uncomfortable, such as when lying down or reclining. Additionally, the design is versatile enough to suit both hot and cold beverages, making it a convenient option for a variety of drinks.

Comparison with Traditional Straight Straws:

In contrast to the conventional straight straws, U-shaped drinking straws provide a more user-centric experience. While straight straws may require users to contort their bodies for effective sipping, U-shaped straws adapt to the user's posture, promoting a more natural and comfortable drinking motion. This adaptability also reduces the risk of spills and choking incidents, making them a safer choice, especially for individuals with limited motor control.

Visual Representation:

Visualizing the U-shaped design is crucial to understanding its significance. Picture a straw with a gentle bend in the middle, resembling the letter 'U.' This bend facilitates an ergonomic and functional approach to drinking, catering to a broader audience and a wider range of situations.

The next section of our blog will take us through the exciting realm of applications where U-shaped drinking straws truly shine. From healthcare settings to day-to-day convenience, these straws have found their way into various industries, addressing specific needs and revolutionizing the way we sip our favorite beverages. Join us as we explore the diverse landscapes these straws have conquered.

Applications of U-shaped Drinking Straws:

The innovation of U-shaped drinking straws has brought about a paradigm shift in how we approach beverage consumption. This design, once seen as a simple alteration, has sparked a revolution across multiple industries, each benefiting from the unique advantages these straws offer.

|

1. Healthcare and Medical Settings:

U-shaped drinking straws have found a significant role in healthcare environments. For patients with mobility limitations, such as those bedridden or with reduced motor control, these straws provide a dignified and practical solution. Medical professionals often opt for U-shaped straws to ensure patients can enjoy beverages comfortably without compromising their posture or recovery process.

2. Special Needs and Disabilities:

Individuals with disabilities or special needs often face challenges while consuming liquids. U-shaped drinking straws address these challenges by accommodating different postures and making drinking more accessible. This inclusivity enhances the overall quality of life for those with varying abilities.

3. Hospitality and Food Services:

In the hospitality sector, the guest experience is paramount. U-shaped straws elevate the dining experience, allowing patrons to enjoy their drinks without awkward adjustments. These straws are particularly popular in upscale restaurants, hotels, and catering services where attention to detail matters.

4. Home Use and Convenience:

Beyond specific industries, U-shaped straws have also made their way into homes. Whether it's parents ensuring their young children can comfortably sip from a cup or individuals seeking a more relaxed way to enjoy beverages, these straws cater to everyday convenience.

5. Elderly Care:

As our population ages, the importance of products catering to the elderly becomes more evident. U-shaped straws offer seniors a comfortable and spill-free way to hydrate, promoting independence and maintaining their dignity.

6. Travel and On-the-Go:

For those constantly on the move, U-shaped straws are a travel essential. Whether on a plane, train, or in a car, these straws allow for easy sipping without requiring users to tilt their heads or worry about spills.

7. Sports and Active Lifestyles:

Athletes and fitness enthusiasts often require quick and convenient hydration. U-shaped straws fit into water bottles and hydration packs, ensuring smooth sipping during workouts or outdoor activities.

8. Sustainability Initiatives:

Some manufacturers offer U-shaped straws made from eco-friendly materials, aligning with sustainability goals. This showcases the versatility of these straws in catering to both functional and environmental concerns.

In the subsequent sections of this blog, we'll delve into the intricate production process of U-shaped drinking straws. From the initial straw extrusion to the final packing in cartons, we'll uncover the stages that transform raw materials into these functional and adaptive tools. Join us as we explore the manufacturing journey that gives life to U-shaped drinking straws.

The U-shaped Drinking Straw Production Process

Step-by-step breakdown of the entire production process:

|

|||

|

|

|

|

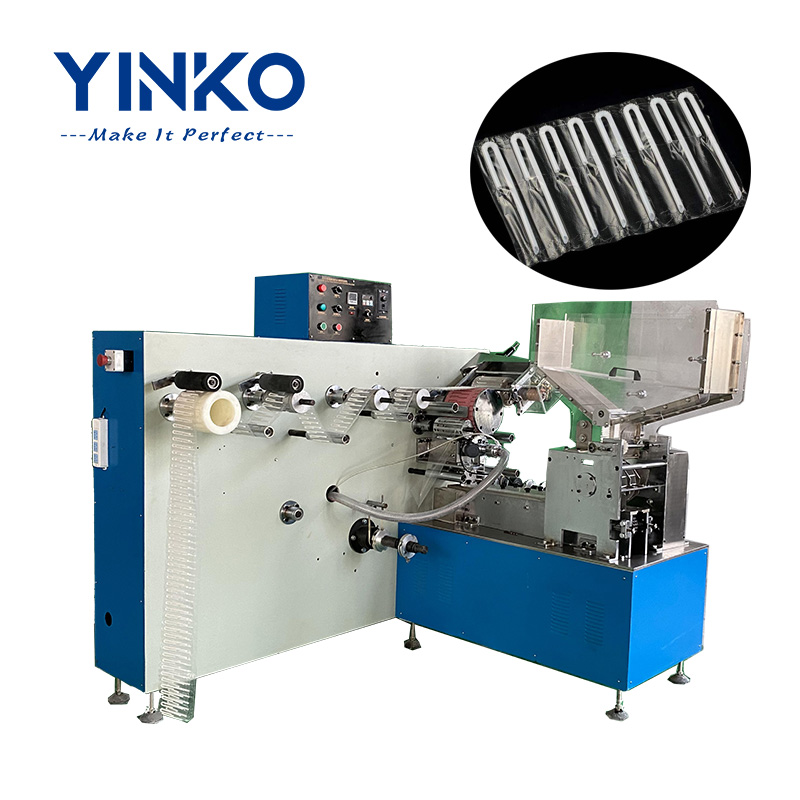

| 1. Straw extrusion machine: Making the straight straw | 2. Flexible straw bending machine: Bend the straight straw into flexible | 3. U-shaped straw bending & packing machine: Formation of the U-shape and packaging. | 4. Straw Auto Carton Packing Machine: Final packing in carton, Bulk packaging for distribution. |

Factors to Consider Before Getting a U-shaped Drinking Straw Production Line:

Investing in a U-shaped drinking straw production line is a significant decision that requires careful consideration of various factors. To ensure a successful venture into this innovative industry, here are the key aspects you need to evaluate before making your investment:

1. Quality Standards and Certifications:

Ensure that the production line adheres to relevant quality standards and certifications for the industry. These standards guarantee that your U-shaped straws meet safety and hygiene requirements, boosting your credibility among clients and end-users.

2. Production Capacity and Speed:

Determine your required production capacity and speed. then will know how many lines are required.

3. Customization Options:

Consider whether the production line allows for customization of U-shaped straw designs. Depending on your target market, the ability to offer unique designs, colors, and features could give you a competitive edge.

4. Energy Efficiency and Sustainability:

As environmental concerns grow, opt for a production line that integrates energy-efficient practices and sustainable materials. A commitment to eco-friendly production can enhance your brand reputation and appeal to environmentally conscious consumers.

5. Maintenance and Support Services:

Evaluate the availability of maintenance and support services. A reliable supplier should provide training for your staff, technical assistance, and access to spare parts to minimize downtime and keep your production running smoothly.

6. Cost Analysis:

Perform a thorough cost analysis that includes the initial investment, operational costs, maintenance expenses, and potential returns. This analysis will help you gauge the financial viability of your production line.

7. Market Research:

Conduct comprehensive market research to understand the demand for U-shaped drinking straws in your target industries. Identifying potential clients and their requirements will guide your production line choices.

8. Supplier Reputation and Reviews:

Choose a reputable supplier with a track record of delivering high-quality production lines. Look for reviews and testimonials from other clients to gauge their satisfaction and the performance of the equipment.

9. Regulatory Compliance:

Ensure that the production line meets all regulatory requirements and safety standards in your region. This includes aspects such as machine safety, worker safety, and environmental regulations.

10. Technology and Innovation:

Consider the technological features of the production line. Advanced automation and smart technology can improve efficiency and reduce human error in the production process.

By carefully evaluating these factors and making informed decisions, you can set the foundation for a successful U-shaped drinking straw production venture. In the following section, we'll address some of the most common questions that arise when considering such a production line, providing you with insights to guide your decision-making process.

Frequently Asked Questions

1. What information shall we provide if want to set up a line for u shaped straw making?

--- straw information, like straw material, straw size,straw packing, expected production capacity, your local voltage, etc

2. Can this U shaped straw packing machine works on different sizes straws?

--- it can bend and pack different sizes straw after changing some parts.

3. Is it easy to operate these machines?

--- Workers can operate these machine easily after get trained.

4. Can you give technical support and training support?

--- Yes, absolutely ,we can give technical support at any time. Service is very important

Conclusion

In this guide, we've unveiled the world of U-shaped drinking straws, showcasing their versatility and unique applications. These straws have evolved to offer comfort and convenience, catering to various industries and lifestyles.

Whether it's healthcare, special needs, hospitality, or sustainability, U-shaped straws have made their mark, revolutionizing how we sip beverages. If you're considering entering the U-shaped straw production industry, remember to prioritize quality, capacity, customization, and sustainability.

We invite you to explore the potential of U-shaped straw production, whether as a consumer seeking better sipping or an entrepreneur looking to innovate. The U-shaped straw is here to stay, offering adaptability and enhanced functionality for a wide range of scenarios. Embrace this exciting evolution in drinking straws and join the revolution.

if you need a complete solution for the line, please feel free to contact us.