4 in 1 Laser Welding Machine

Laser welding machine is designed to be lightweight and compact, making them easy to carry to different job sites or within a workshop.These machines are user-friendly and require minimal setup compared to traditional welding equipment. This makes them suitable for both professionals and beginners.

Handheld laser welding provides precise control over the welding process, allowing for fine and intricate welds in various materials. Handheld laser welding machines can often perform welding tasks faster than traditional methods, which can lead to increased productivity. Laser welding is generally safer for operators, as it reduces exposure to harmful fumes and radiation.

Laser Welding Laser Cleaning Laser Cutting Seam Cleaning

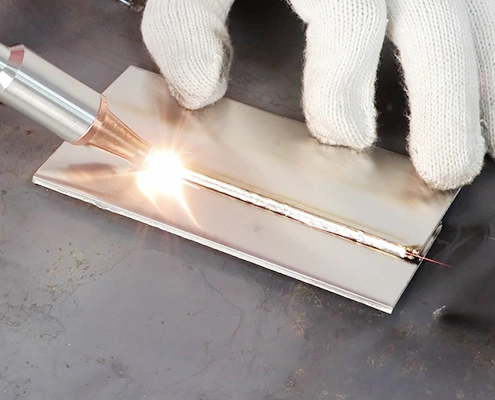

Laser Welding:The primary function is welding. It is designed to join materials together using a high-powered laser beam, ensuring a precise and efficient welding process.

Laser Cleaning:In addition to welding, this tool can also perform cleaning tasks. It can remove rust, contaminants, or unwanted material from the surface of the workpiece before or after welding, ensuring a clean and smooth welding surface.

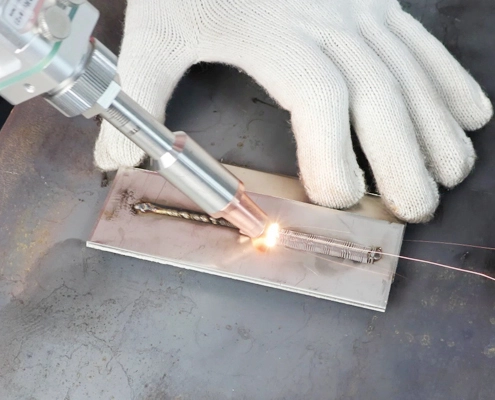

Laser Cutting:Another capability of this tool is cutting. It can be used to cut materials with high precision, making it a versatile tool for various applications that require both welding and cutting.

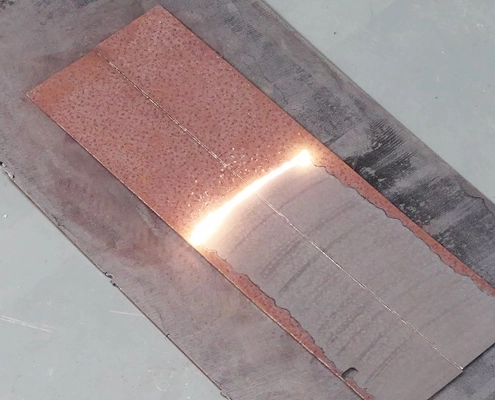

Seam Cleaning:Seam cleaning is a specific function related to welding. After welding, the tool can clean the welded seam to ensure a polished and finished appearance.

Traditional Welding VS Laser Welding

| PROJECT | TIG/MIG | Laser welding machine |

| Labor cost | Difficult to recruit and high salary | Simple operation and low labor cost |

| Disease | Frequent occupational diseases and serious physical injuries | Less radiation, only need protective glasses to filter strong light |

| Speed | Slow speed, low efficiency | 4-10 times faster than traditional welding |

| Hot zone | Large | Small |

| Deformation | Easy to deform | Not easy to deform |

| Quality | The weld is thick and irregular, and needs polishing | Fine and beautiful welds, high welding strength |

| Damage | There is air hole and it is easy to weld through | Welding is uniform and consistent |

| Application | Limited by consumables | Wide application range |

| Master | Professional welders are required | 30 minutes of learning can be mastered skillfully |

Advantages of the Laser Welding Machine

1. Portability: The mini handheld welding machine is compact and lightweight, making it easy to carry and operate in various work environments.

2. High Efficiency: The machine utilizes laser technology, which enables fast and precise welding, 4-10 times faster than traditional welding, leading to increased productivity and reduced welding time.

3. Cost-effective: By improving welding efficiency and reducing processing time, the mini handheld welding machine helps to lower production costs and optimize resource allocation.It saves about 80%~90% electricity than argon arc welding.

4. Ease of Use: The machine is designed with user-friendly touch screen controls and intuitive interfaces, making it easy for operators to learn and operate without extensive training.

5. Versatility: The mini handheld welding machine is suitable for various materials, including metals and alloys, allowing for a wide range of welding applications in industries such as automotive, electronics, and jewelry.

6. Flexibility: The machine offers flexibility in terms of welding positions and angles, allowing for welding in tight or difficult-to-reach spaces, improving accessibility and overall welding capabilities.

7. Precise and Quality Welds: The laser technology used in the machine ensures precise and high-quality welds, resulting in strong and durable joints with minimal distortion or damage to the surrounding material.

8. Safety Features: Multiple safety guarantees to protect the safety of operators and equipment.

Gefasst fiber laser welding head

The product covers welding head/cleaning head and self-developed control system, and sets up multiple safety alarms and main Dynamic safety power-off and light-off settings. It is developed on the basis of the hand-held welding head that our company has produced in large quantities, and has the characteristics of high reliability and strong stability. This product can be adapted to various brands of fiber lasers, and the optical and water-cooled design is optimized so that the laser head can be work stably for a long time at 2000W.

Laser Welding Copper Nozzles

Nozzle Variety:Laser welding heads can be fitted with a variety of nozzles, including angle nozzles and cleaning nozzles. These options allow for flexibility in welding different products and handling various materials.

Application Flexibility: The availability of different nozzles enhances the versatility of laser welding equipment, making it suitable for a wide range of materials and welding needs.

Optimized Performance: The use of specialized nozzles helps optimize the welding process by improving the control and precision of the laser beam.

Sample Display

| Material | Thickness Single side weld | Thickness Double side weld |

Thickness Wire weld |

| Stainless steel | 3mm | 3mm |

2.5mm |

| Galvanized steel | 3mm | 6mm |

2.5mm |

| Mild steel | 3mm | 6mm |

2.5mm |

| Titanium alloy | 3mm | 6mm |

2.5mm |

| Aluminum |

2mm |

4mm |

1.8mm |

| Copper | 1mm | 2mm | 0.8mm |