Fiber laser cleaning is the process by which a surface is cleaned by having any impurities, oxides, dust, oil or other materials removed. This is done by using a fiber laser with high repetition rates and high peak powers, but in short pulses, so as to not damage the substrate that is being worked with. Laser cleaning is one of the modern versions of the cleaning process and has rapidly replaced traditional methods such as dry-ice blasting or media blasting due to the numerous benefits that it provides.

It offers these benefits as it works in a significantly different way to the processes that have preceded it. Furthermore, using a fiber laser as the medium also works in a much different way to other types of laser cleaning methods. We have explored this in more detail below and explained why fiber laser cleaning is the most efficient, safe and cost-effective cleaning solution on the market.

A key question that we are frequently asked is “How does laser cleaning work differently to the other more traditional methods?”. There are some key problems that lasers have helped to address and solve.

Firstly, other methods were contact processes, meaning they were abrasive and damaging to the materials that they were working with. Take media blasting, for example, which essentially acts like a pressure washer, but with pressurized air, to blast a material until it is clean. It gets the job done, but it often affects the material that you don’t want to damage below!

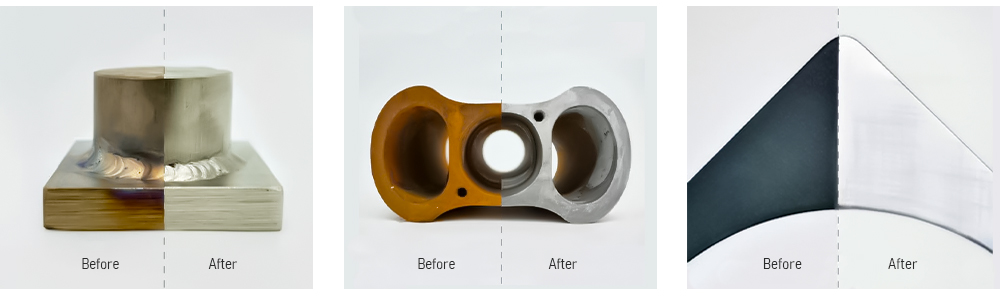

Laser cleaning, on the other hand, is non-contact and non-abrasive, and so will only irradiate the material that you want to get rid of.

You also have a great deal of control over the beam, meaning you can achieve the desired depth that you want to. Further to this, you can irradiate the whole surface layer of a material, or a much thinner layer, say the top coat of paint, but not the primer below. Or, should you wish, you can just clean a very small section. If using another process which simply blasts the material, it is hard to enjoy such a high level of control.

One of the key benefits in the way that laser cleaning works is that not much waste is left over due to the irradiation process; the substrate is simply vaporized rather than left as waste. The majority of the waste that is left over comes as dust particles and can be easily collected and removed by the user.

There are many reasons that fiber lasers have quickly gained popularity over other types of laser. The fiber laser beam is generated inside the fiber itself, and so the beam produced is extremely stable. Other laser sources, on the other hand, rely on a fine alignment of mirrors, and should these be knocked, it can be hard to realign them.

The stable beam that is produced is also of an extremely high quality too. It’s straight, it can be highly accurate to a small degree, and it offers a high level of power too. Finally, they are an efficient source too. They are easy to cool and have a much longer service life than other types of laser.

If you would like to find out more about the laser cleaning process, or our range of fiber lasers, then please simply leave a message below.